Foundations

Software-Defined Manufacturing

The ideas guiding the next industrial revolution.

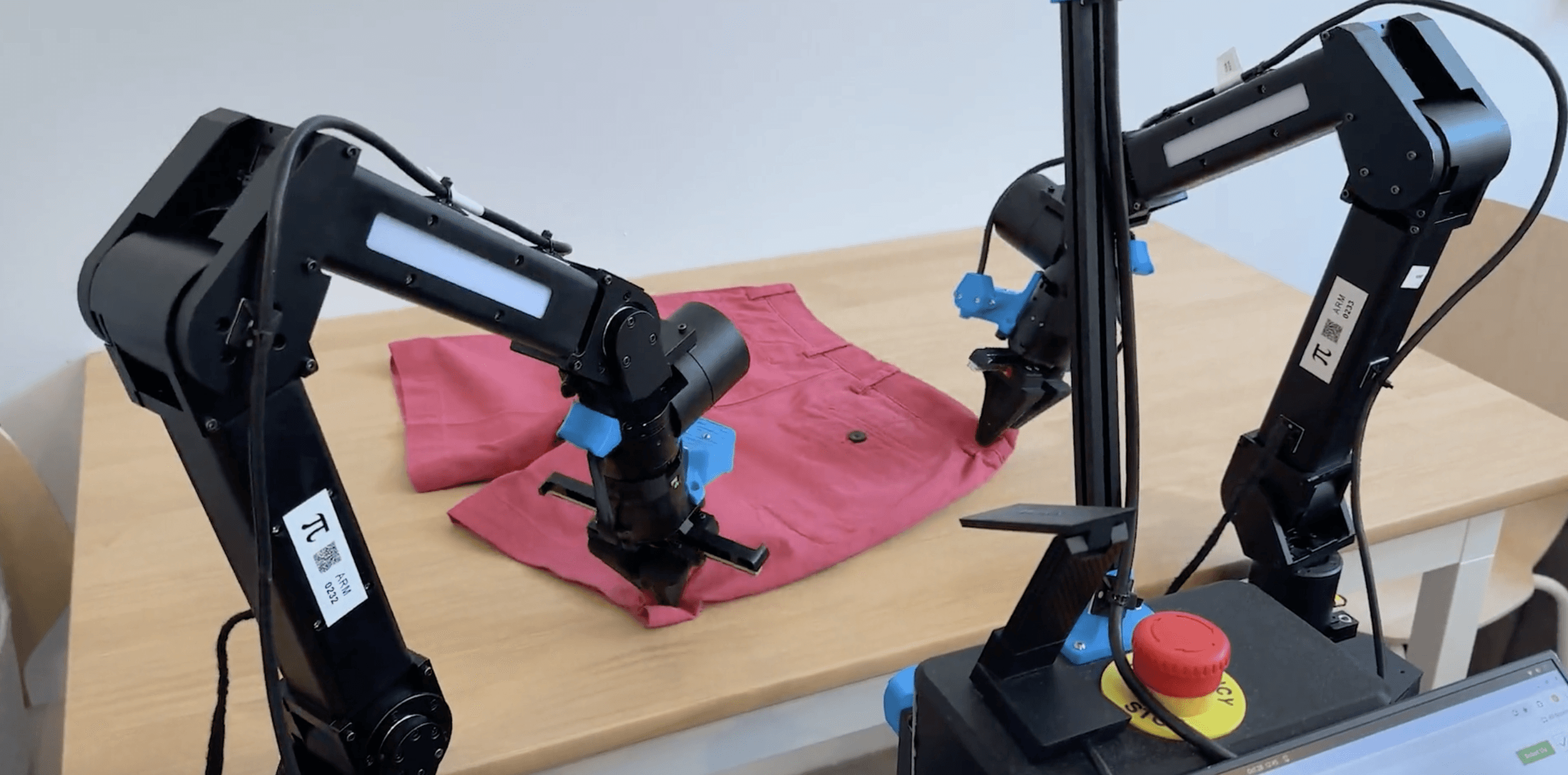

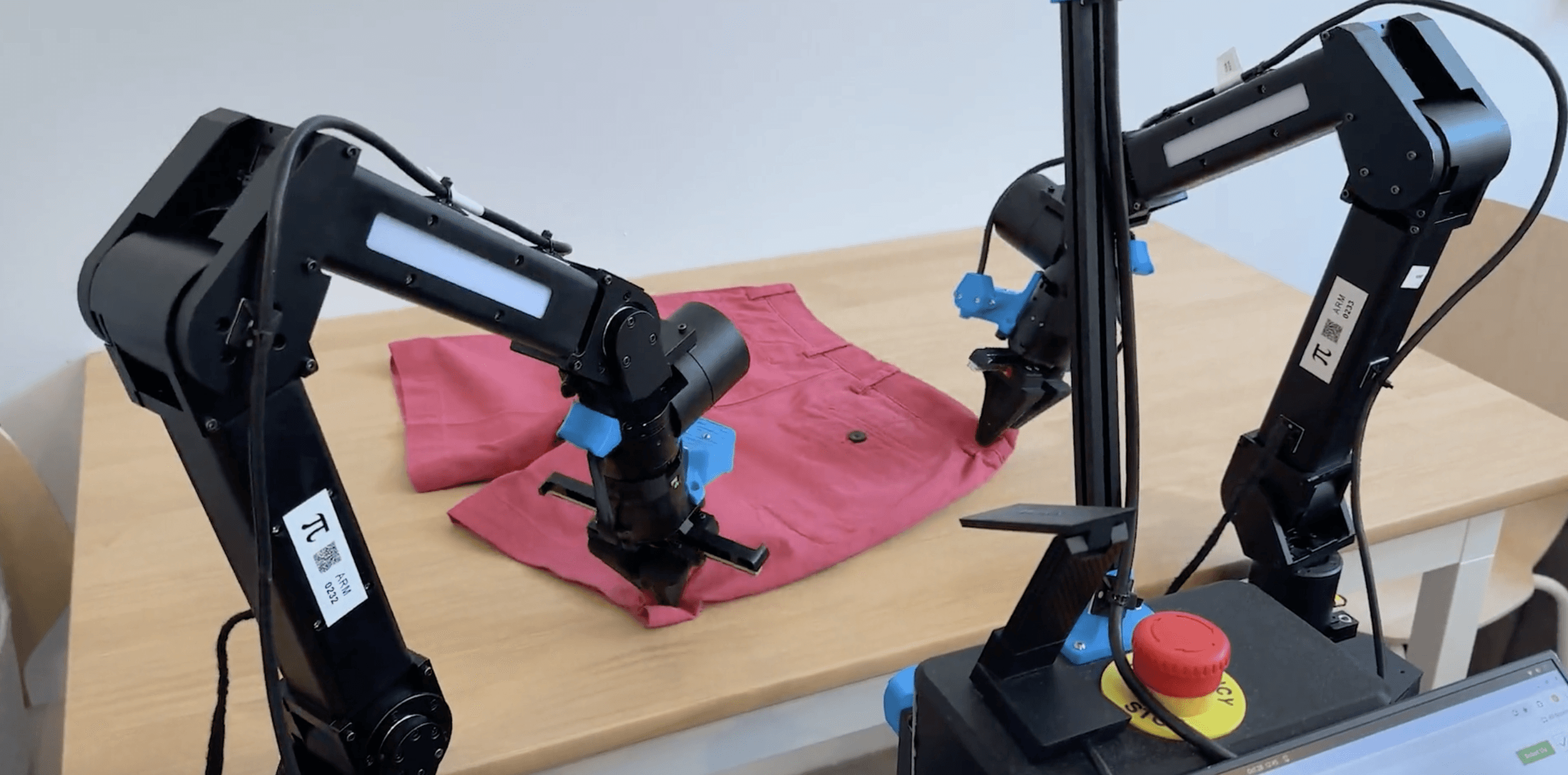

DeepMind’s RoboBallet and the Next Wave of Coordination

Inside the cell: While Foundational has focused on AI-native robotics for extensible manufacturing beyond the core work cell, RoboBallet, a research project from our friends at DeepMind, offers a glimpse of what’s coming next—multi-agent robotic arms coordinating within the cell itself.

From static code to adaptive motion: The shift from pre-programmed paths to collaborative, learned behavior points to a future where robotic choreography is emergent, not engineered.

Expanding the circle: While our near-term focus remains on generalizable manufacturing systems, advances like this hint at a deeper transformation—one where even traditionally SKU-specific hardware becomes fluid, adaptive, and part of an extensible whole.

Source: “RoboBallet: Planning for multirobot reaching with graph neural networks and reinforcement learning”

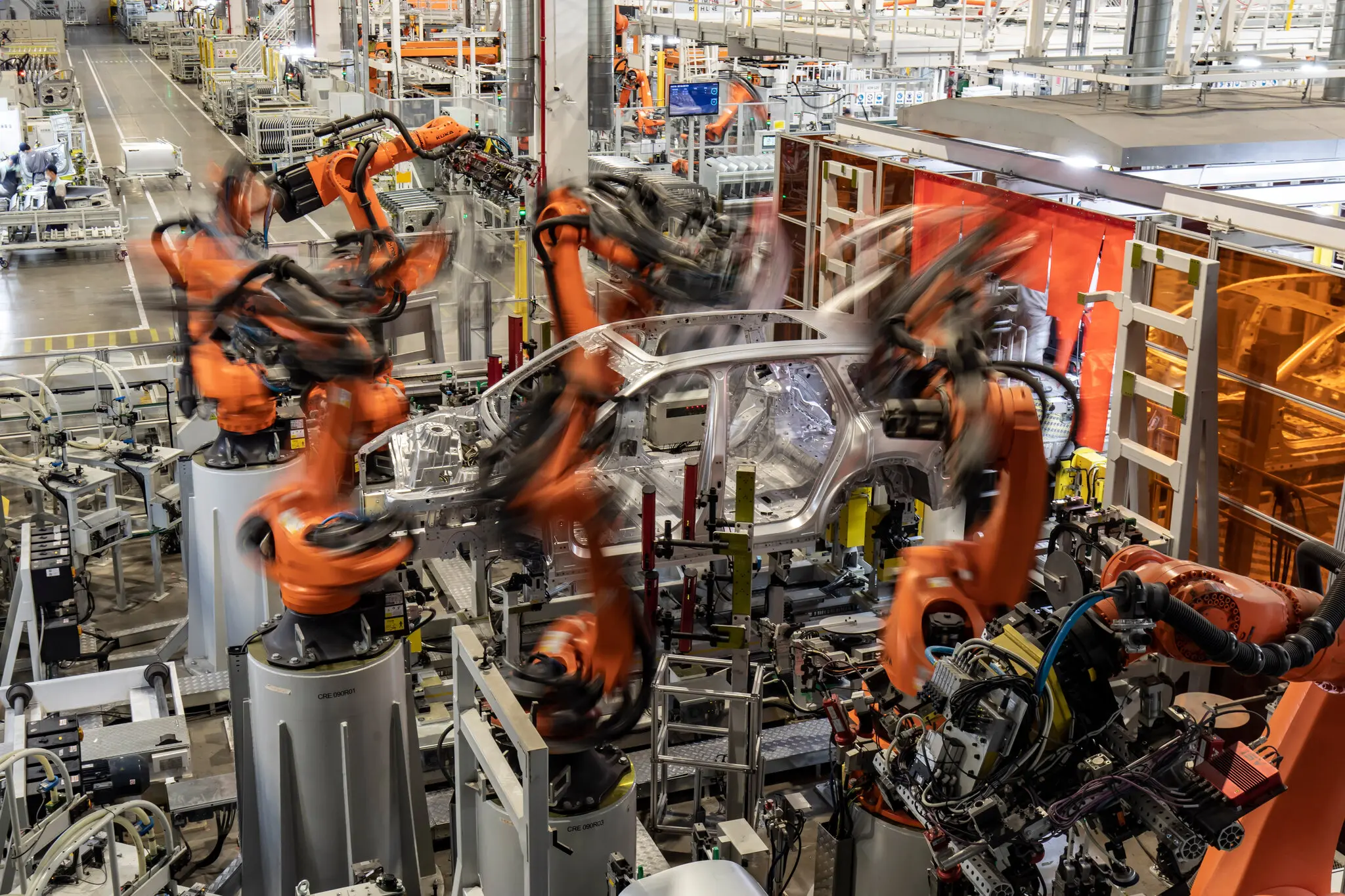

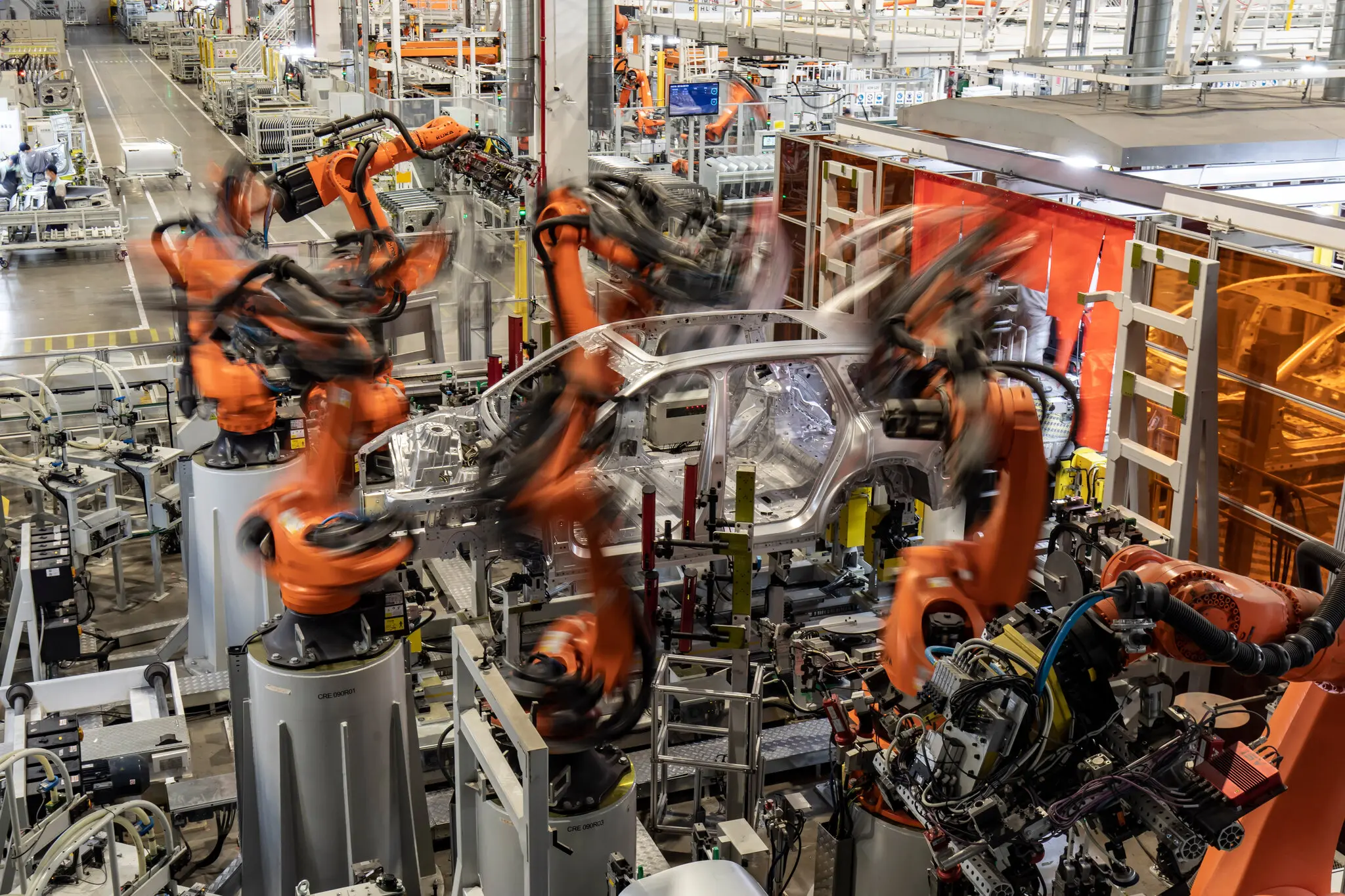

China’s Robotics Surge and the U.S. Industrial Gap

Industrial gap, made visible: Another reminder of the widening U.S. deficit in industrial automation relative to China. Not news to those in the field—but the fact that it’s entering the mainstream conversation amid trade tension and geopolitical rivalry is.

Ecosystems, not factories: China’s advantage isn’t just cheap labor or state policy; it’s the interconnected ecosystem that links hardware, supply chains, and capital formation into a continuous automation flywheel.

Leapfrog, don’t copy: The opportunity for the U.S. isn’t to replicate last-generation static systems, but to vault ahead—to build AI-native, adaptive robotics that render legacy automation architectures obsolete.

Source: "There Are More Robots Working in China Than the Rest of the World Combined"

A16Z’s Ben & Marc on the AI robotics and the Future of US Manufacturing

An oldie but a goodie: Ben and Marc—founders of a16z, with one of the most forward-looking AI-robotics portfolios—offer one of the clearest conversations yet on the coming convergence of AI and robotics

From perception to physics: Around the one-hour mark, Ben delivers a sharp primer on Robot Foundation Models—how robots might learn the laws of physics directly from real-world video data rather than abstract simulation.

A blueprint for reindustrialization: At 1:12, Marc argues that America’s manufacturing revival depends on fully AI-native factories. We share his call for an Operation Warp Speed for Manufacturing—a national effort that, while uniquely suited to U.S. strengths in AI, will demand a new generation of trade schools training the “manufacturing technologists” who will make it real.

Physical Intelligence and the ChatGPT Moment for Robotics

A watershed moment: Physical Intelligence’s emergence from stealth marked the closest thing yet to a ChatGPT moment for robotics—a public proof that generalized robotic intelligence is moving from research to reality.

From domestic to industrial: While the company and the broader RFM ecosystem have since evolved, this announcement still stands as a north star for what’s next: robotic understanding of physics which will ultimately transcend these illustrative domestic tasks and begin to operate in complex industrial environments.

Direction of travel: The trajectory is clear—foundation models will become the substrate for physical intelligence, turning robots from task executors into adaptive agents capable of learning, collaborating, and reasoning about the physical world.

The Physics of Production

Reclaiming the “next industrial revolution”: The phrase gets overused, but this essay earns it—a rare, rigorous look at why AI-native robotics represents a genuine break from prior industrial paradigms.

Decoupling production from constraint: By merging intelligence with actuation, we begin to separate manufacturing from many of its historic limits—geometry, geography, even human scheduling. Production becomes software-defined.

Why it matters: This is the quiet transformation beneath the hype: AI-native robotics doesn’t just make factories smarter—it changes what a factory is, unlocking a new physics of production itself.

To Humanoid or Not? Is that the question?

To humanoid or not? Rodney Brooks questions the prevailing assumption: humanoid form factors don’t guarantee dexterity or generalizability, even if our world is built for human dimensions.

Video isn’t enough: He argues that visual learning alone, without rich tactile and force feedback, can’t bridge the gap to dexterous manipulation—especially in unstructured environments.

What this means for us: In industrial domains, we’re more interested in pragmatic capability than human mimicry. Although we’re open to experimentation with humanoids (reach out, folks!), our bets so far favor specialized, form-adapted manipulators—while keeping an eye on whether future hybrids or new sensor modalities shift the calculus.

COSMOS and the Self-Learning Factory

Factory data, unlocked: The COSMOS launch marks real progress on one of the hardest problems in industrial AI — the shortage of high-quality training data. By fusing real sensor input with simulated worlds, COSMOS can generate the data robots need to learn, rather than waiting for factories to produce it.

Learning at the edge: Paired with NVIDIA’s Jetson platform at the robot edge, COSMOS moves intelligence out of the cloud and onto the robots themselves. Models can now learn, adapt, and refine in real time — directly on the factory floor.

Toward self-improving factories: Together, COSMOS and Jetson create a feedback loop where every robot not only executes work but also captures and creates data that makes the entire system smarter over time. It’s an early architecture for AI-native manufacturing that pairs edge compute and sensor fusion with more general Robotic Foundation Models.

Source: "Generating Synthetic Data for Physical AI With NVIDIA Cosmos"

Crossing the Robotics Threshold

Crossing the robotics threshold: This essay frames robotics not as incremental tech, but as a seismic global pivot. China isn’t just installing more arms—it’s building the ecosystem that makes autonomous supply chains inevitable.

Ecosystems beat exports: China’s lead isn’t from a few hero robots, but from orchestrating policy, capital, standardization, and deployment into one self-reinforcing fabric.

A warning and an opportunity: The U.S. risks becoming a dependent consumer of automation unless it leapfrogs by embracing AI-native robotics. The clock is ticking—crossing the robotics threshold matters more than ever.

Source: "The Robotics Threshold: China's Rise, America’s Reckoning"

America Cannot Lose the Robotics Race

Robotics is the next great race: Martin Casado and Anne Neuberger argue that AI doesn’t end with language models but extends into the physical world. The nations that master intelligent machines will define the next industrial era.

China’s playbook is full-stack: They point out that China isn’t just deploying more robots; it’s building the entire stack of materials, components, and state-backed manufacturing policy to own the future of automation.

America’s moment to lead: The U.S. can still win this race, but only by coordinating policy, capital, and talent around AI-native robotics. It’s not about catching up; it’s about leaping ahead.

Rewriting the Robotics Playbook

From promise to playbook: McKinsey highlights an important shift in robotics: moving from visionary prototypes to scalable, real-world performance. The question is no longer if general-purpose robotics can exist, but how to make them safe, reliable, and economically viable.

Embodied intelligence as the next frontier: The report defines “general-purpose robotics” and “embodied AI” as the merging of perception, decision-making, and physical action. It’s about teaching machines to operate in the real world rather than follow prewritten scripts.

Bridging simulation and reality: Among the core challenges are translating learned behaviors from simulation to the messy conditions of real factories, and solving energy constraints that limit run time. These are precisely the bottlenecks AI-native robotics must overcome to reach commercial scale.

Source: "Rewriting the robotics playbook: From promise to performance"

DeepMind’s RoboBallet and the Next Wave of Coordination

Inside the cell: While Foundational has focused on AI-native robotics for extensible manufacturing beyond the core work cell, RoboBallet, a research project from our friends at DeepMind, offers a glimpse of what’s coming next—multi-agent robotic arms coordinating within the cell itself.

From static code to adaptive motion: The shift from pre-programmed paths to collaborative, learned behavior points to a future where robotic choreography is emergent, not engineered.

Expanding the circle: While our near-term focus remains on generalizable manufacturing systems, advances like this hint at a deeper transformation—one where even traditionally SKU-specific hardware becomes fluid, adaptive, and part of an extensible whole.

Source: “RoboBallet: Planning for multirobot reaching with graph neural networks and reinforcement learning”

China’s Robotics Surge and the U.S. Industrial Gap

Industrial gap, made visible: Another reminder of the widening U.S. deficit in industrial automation relative to China. Not news to those in the field—but the fact that it’s entering the mainstream conversation amid trade tension and geopolitical rivalry is.

Ecosystems, not factories: China’s advantage isn’t just cheap labor or state policy; it’s the interconnected ecosystem that links hardware, supply chains, and capital formation into a continuous automation flywheel.

Leapfrog, don’t copy: The opportunity for the U.S. isn’t to replicate last-generation static systems, but to vault ahead—to build AI-native, adaptive robotics that render legacy automation architectures obsolete.

Source: "There Are More Robots Working in China Than the Rest of the World Combined"

A16Z’s Ben & Marc on the AI robotics and the Future of US Manufacturing

An oldie but a goodie: Ben and Marc—founders of a16z, with one of the most forward-looking AI-robotics portfolios—offer one of the clearest conversations yet on the coming convergence of AI and robotics

From perception to physics: Around the one-hour mark, Ben delivers a sharp primer on Robot Foundation Models—how robots might learn the laws of physics directly from real-world video data rather than abstract simulation.

A blueprint for reindustrialization: At 1:12, Marc argues that America’s manufacturing revival depends on fully AI-native factories. We share his call for an Operation Warp Speed for Manufacturing—a national effort that, while uniquely suited to U.S. strengths in AI, will demand a new generation of trade schools training the “manufacturing technologists” who will make it real.

Physical Intelligence and the ChatGPT Moment for Robotics

A watershed moment: Physical Intelligence’s emergence from stealth marked the closest thing yet to a ChatGPT moment for robotics—a public proof that generalized robotic intelligence is moving from research to reality.

From domestic to industrial: While the company and the broader RFM ecosystem have since evolved, this announcement still stands as a north star for what’s next: robotic understanding of physics which will ultimately transcend these illustrative domestic tasks and begin to operate in complex industrial environments.

Direction of travel: The trajectory is clear—foundation models will become the substrate for physical intelligence, turning robots from task executors into adaptive agents capable of learning, collaborating, and reasoning about the physical world.

The Physics of Production

Reclaiming the “next industrial revolution”: The phrase gets overused, but this essay earns it—a rare, rigorous look at why AI-native robotics represents a genuine break from prior industrial paradigms.

Decoupling production from constraint: By merging intelligence with actuation, we begin to separate manufacturing from many of its historic limits—geometry, geography, even human scheduling. Production becomes software-defined.

Why it matters: This is the quiet transformation beneath the hype: AI-native robotics doesn’t just make factories smarter—it changes what a factory is, unlocking a new physics of production itself.

To Humanoid or Not? Is that the question?

To humanoid or not? Rodney Brooks questions the prevailing assumption: humanoid form factors don’t guarantee dexterity or generalizability, even if our world is built for human dimensions.

Video isn’t enough: He argues that visual learning alone, without rich tactile and force feedback, can’t bridge the gap to dexterous manipulation—especially in unstructured environments.

What this means for us: In industrial domains, we’re more interested in pragmatic capability than human mimicry. Although we’re open to experimentation with humanoids (reach out, folks!), our bets so far favor specialized, form-adapted manipulators—while keeping an eye on whether future hybrids or new sensor modalities shift the calculus.

COSMOS and the Self-Learning Factory

Factory data, unlocked: The COSMOS launch marks real progress on one of the hardest problems in industrial AI — the shortage of high-quality training data. By fusing real sensor input with simulated worlds, COSMOS can generate the data robots need to learn, rather than waiting for factories to produce it.

Learning at the edge: Paired with NVIDIA’s Jetson platform at the robot edge, COSMOS moves intelligence out of the cloud and onto the robots themselves. Models can now learn, adapt, and refine in real time — directly on the factory floor.

Toward self-improving factories: Together, COSMOS and Jetson create a feedback loop where every robot not only executes work but also captures and creates data that makes the entire system smarter over time. It’s an early architecture for AI-native manufacturing that pairs edge compute and sensor fusion with more general Robotic Foundation Models.

Source: "Generating Synthetic Data for Physical AI With NVIDIA Cosmos"

Crossing the Robotics Threshold

Crossing the robotics threshold: This essay frames robotics not as incremental tech, but as a seismic global pivot. China isn’t just installing more arms—it’s building the ecosystem that makes autonomous supply chains inevitable.

Ecosystems beat exports: China’s lead isn’t from a few hero robots, but from orchestrating policy, capital, standardization, and deployment into one self-reinforcing fabric.

A warning and an opportunity: The U.S. risks becoming a dependent consumer of automation unless it leapfrogs by embracing AI-native robotics. The clock is ticking—crossing the robotics threshold matters more than ever.

Source: "The Robotics Threshold: China's Rise, America’s Reckoning"

America Cannot Lose the Robotics Race

Robotics is the next great race: Martin Casado and Anne Neuberger argue that AI doesn’t end with language models but extends into the physical world. The nations that master intelligent machines will define the next industrial era.

China’s playbook is full-stack: They point out that China isn’t just deploying more robots; it’s building the entire stack of materials, components, and state-backed manufacturing policy to own the future of automation.

America’s moment to lead: The U.S. can still win this race, but only by coordinating policy, capital, and talent around AI-native robotics. It’s not about catching up; it’s about leaping ahead.

Rewriting the Robotics Playbook

From promise to playbook: McKinsey highlights an important shift in robotics: moving from visionary prototypes to scalable, real-world performance. The question is no longer if general-purpose robotics can exist, but how to make them safe, reliable, and economically viable.

Embodied intelligence as the next frontier: The report defines “general-purpose robotics” and “embodied AI” as the merging of perception, decision-making, and physical action. It’s about teaching machines to operate in the real world rather than follow prewritten scripts.

Bridging simulation and reality: Among the core challenges are translating learned behaviors from simulation to the messy conditions of real factories, and solving energy constraints that limit run time. These are precisely the bottlenecks AI-native robotics must overcome to reach commercial scale.

Source: "Rewriting the robotics playbook: From promise to performance"

Interested in learning more?

Interested in learning more?

Interested in learning more?